-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the ever-evolving landscape of industrial applications, the selection of the right Tubing Ball Valve is crucial for optimizing process efficiency and ensuring safety. According to a report by Research and Markets, the global ball valve market is expected to reach USD 16.2 billion by 2025, reflecting a CAGR of 5.3% during the forecast period. This growth is driven by the increasing demand for advanced valve technologies in sectors such as oil and gas, water and wastewater management, and chemical processing.

Selecting the appropriate Tubing Ball Valve entails a careful assessment of various factors, including pressure rating, size, and material compatibility. A comprehensive understanding of the operational environment—be it high-temperature conditions or acidic media exposure—can significantly influence the lifespan and performance of the valve. Moreover, industry experts emphasize that engineers must consider regulatory standards and certifications to ensure compliance and reliability in their operations.

As businesses strive for greater efficiency and sustainability, the decision-making process surrounding the choice of Tubing Ball Valves has never been more critical. By gaining insights into the integral features and specifications of these valves, professionals can make informed choices that align with their operational needs and industry standards, ultimately leading to enhanced system performance and safety.

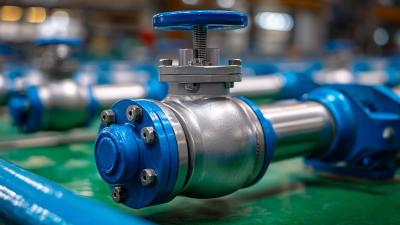

When selecting the right tubing ball valve, it's crucial to understand its key features and functions, as these elements significantly impact operational efficiency and system reliability. A tubing ball valve, designed to control fluid flow with a spherical disc, operates by rotating the ball to either allow or block flow. The primary function of this valve type is to provide a tight seal with minimal leakage, making it essential in industries where precision and safety are paramount.

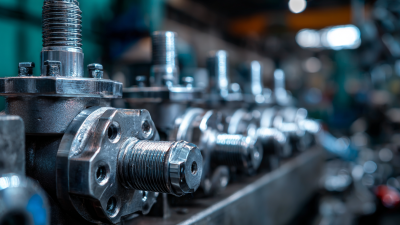

According to a recent market report by GlobalData, the global demand for tubing ball valves is projected to increase by over 4.5% annually through 2025, driven by advancements in oil and gas extraction technologies and increased infrastructure investment. When evaluating valves, consider features such as pressure ratings, temperature tolerance, and material compatibility. These factors play a vital role in ensuring optimal performance in demanding environments. For instance, valves used in high-pressure applications require robust materials, such as stainless steel or special alloys, to withstand corrosive conditions and maintain their integrity.

Furthermore, automation in valve operation is becoming a trending necessity. With the integration of smart technologies, operators can monitor and manage valve functions in real-time, enhancing process efficiency and reducing downtime. A 2022 study from the American Society of Mechanical Engineers highlighted that automated valve control systems could reduce energy consumption by up to 20%, showcasing the potential for substantial cost savings and improved operational outcomes. Understanding these key features and functions will empower you to select a tubing ball valve that meets your specific operational requirements effectively.

When selecting a tubing ball valve, understanding your specific application is crucial. Tubing ball valves are widely used in various industries, notably in oil and gas, chemical processing, and water management. According to a recent industry report by MarketsandMarkets, the global demand for ball valves is projected to reach $15 billion by 2025, driven largely by their reliability in controlling fluid flow in high-pressure environments. Properly identifying where and why to use tubing ball valves can significantly enhance operational efficiency and safety.

For applications involving high-pressure liquids or gases, such as in petrochemical industries, opting for the right size and type of tubing ball valve can prevent leaks and enhance system integrity. In water treatment facilities, these valves play a critical role in managing water flow, ensuring compliance with regulatory standards. Tapping into resources such as the American Petroleum Institute (API) guidelines can provide valuable insights into the specifications necessary for your application.

**Tips:** When selecting a tubing ball valve, consider factors like pressure rating, temperature range, and material compatibility. Always verify these specifications against industry standards to ensure optimal performance. Additionally, consult with experts or review engineering reports to understand the history of similar applications and their outcomes. This will provide a clearer picture of which valve types work best under specific conditions.

When selecting a tubing ball valve, the choice of materials is vital for ensuring longevity and reliability in various applications. According to the International Journal of Advanced Manufacturing Technology, materials used in valve construction can significantly affect their resistance to corrosion and wear, particularly in harsh environments. For instance, stainless steel valves are often favored in industries dealing with aggressive chemicals, thanks to their excellent corrosion resistance and strength. Data highlights that valves made from high-grade stainless steel can last up to 30% longer than those made from lower-quality materials when exposed to corrosive substances.

In addition to stainless steel, other materials like brass and PVC are also popular depending on the service conditions. A study by the American Society of Mechanical Engineers (ASME) indicates that brass valves show superior performance in low-pressure applications due to their durability and ease of maintenance. Meanwhile, PVC valves are recommended for low-pressure water systems as they are lightweight and resistant to certain chemicals, albeit with a lower temperature threshold. Ultimately, understanding the specific requirements of your application—such as pressure, temperature, and exposure to chemicals—is critical. By carefully selecting the right material, one can ensure the proper functioning of the ball valve, thus minimizing maintenance costs and enhancing system reliability.

When selecting a tubing ball valve for your system, understanding the pressure and temperature ratings is essential to ensure optimal performance and safety. According to the American Society of Mechanical Engineers (ASME), proper ratings are crucial for the reliable operation of valves in industrial applications. A valve's pressure rating typically refers to the maximum pressure it can withstand while being operable. Industry standards, such as API 6D, provide guidelines specifying the needs for various types of fluids and conditions, indicating that many valves can operate at pressures ranging from 150 psi to over 10,000 psi, depending on their design and materials.

Temperature ratings, on the other hand, must align with the specific operating environment of your system. The American National Standards Institute (ANSI) outlines a temperature grading system where materials are categorized based on their ability to retain strength and integrity at high temperatures. Many common materials used in valve manufacturing, such as carbon steel and stainless steel, have operational ranges that can extend from -20°F in cryogenic applications up to 900°F in high-temperature environments. It is vital to match the valve's temperature rating with the expected temperature of the media being handled, as failure to do so can lead to catastrophic leaks or valve failure, potentially resulting in costly downtime and safety hazards.

| Valve Type | Pressure Rating (psi) | Temperature Rating (°F) | Material | Connection Type |

|---|---|---|---|---|

| Standard Tubing Ball Valve | 2000 | 150 | Carbon Steel | NPT |

| High-Pressure Tubing Ball Valve | 5000 | 200 | Stainless Steel | Welded |

| Cryogenic Tubing Ball Valve | 3000 | -320 to 150 | Brass | Flanged |

| Municipal Tubing Ball Valve | 150 | 180 | PVC | Socket Weld |

| Oil & Gas Tubing Ball Valve | 4000 | 250 | Alloy Steel | Threaded |

When it comes to the installation of tubing ball valves, proper preparation is essential for ensuring optimal performance and longevity. First, it is crucial to assess the installation environment and verify that the valve is compatible with the fluid type and operational pressures. Proper alignment during installation helps prevent unnecessary stress on the valve components, which can lead to premature failure. Additionally, employing the right sealing materials can enhance the integrity of the connections and minimize the risk of leaks. Always adhere to manufacturer guidelines regarding torque specifications and installation techniques for the best results.

Maintenance is equally important, as regular checks can prevent issues before they escalate. Periodic inspections should focus on identifying any signs of wear or corrosion, as well as ensuring that the valve operates smoothly without any obstructions. A straightforward routine might include lubricating moving parts and ensuring that the actuators respond properly. It’s also advisable to clean the valve periodically to remove any debris that might affect performance. Developing a maintenance schedule tailored to your specific application can significantly extend the life of the valve and improve overall system efficiency.