-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

When selecting the right Screwed Ball Valve for your project, it is essential to consider various factors. According to a report by the Global Valve Market, the demand for ball valves is projected to reach $15 billion by 2025. The increasing need for efficient fluid control drives this trend. Screwed ball valves, known for their reliability, can be crucial to achieving operational efficiency.

In many industries, such as oil and gas, water treatment, and manufacturing, choosing the proper valve means ensuring system integrity. A poorly chosen valve can lead to leaks, costly repairs, and downtime. Research from the Valve Manufacturers Association indicates that nearly 20% of valve failures occur due to improper selection.

Understanding the specific requirements of your application is vital. Consider factors like temperature, pressure rating, and medium compatibility. An incorrect choice might lead to issues down the line. A detailed project evaluation can help in making an informed decision. Accurate selection of a Screwed Ball Valve can make a significant difference in project success.

Screwed ball valves are essential components in various industries. They offer a reliable sealing solution for many fluid control applications. Understanding their structure and uses is crucial for selecting the right type for your project. These valves are commonly used in oil and gas, water treatment, and manufacturing sectors. According to a recent industry report, the global market for ball valves is expected to reach over $12 billion by 2025. This data indicates a growing demand driven by infrastructural development and increased automation.

When evaluating screwed ball valves, consider the materials and pressure ratings. Common materials include brass, stainless steel, and PVC. Each material has specific applications. For instance, stainless steel is preferred for high-temperature and corrosive environments. However, some installations reveal that improper material selection can lead to leaks or valve failures. Regular maintenance is often overlooked, causing premature wear of the valve seats. Inadequate maintenance can significantly impact workflow. Such issues highlight the importance of thorough research and planning when choosing the right valve for your needs.

Another critical aspect is the valve size. A miscalculation in sizing can lead to inefficient flow control. Smaller valves may result in higher pressure drop. Conversely, oversized valves can be costly and occupy unnecessary space. Striking a balance is vital for optimal performance. Additionally, operators should not ignore installation nuances. Misalignment can cause operational issues and damage over time. Industry studies suggest that proper installation processes can increase the lifespan of valves by up to 30%.

When selecting a screwed ball valve, several key considerations come into play. The application type significantly influences your choice. For example, high-pressure systems require valves that can withstand greater stress and temperature variations. According to recent industry reports, nearly 30% of valve failures stem from improper selection based on pressure ratings.

Material compatibility is another crucial factor. Valves are made from various materials, including stainless steel, brass, and PVC. Each material has unique properties that suit different environments. For example, stainless steel is highly resistant to corrosion, making it ideal for chemical processes. The wrong choice could lead to leakage or early failure, contributing to costly downtime.

Installation and maintenance needs also warrant attention. Screwed ball valves often simplify installation due to their threaded ends. However, the ease of maintenance varies. Some designs require specialized tools for servicing. A survey indicates that 15% of technicians encounter difficulties during maintenance, leading to excess repair time. Reflecting on these challenges can help make a more informed decision.

Choosing the right material for a screwed ball valve is critical. The material impacts performance and longevity. Common materials include stainless steel, brass, and plastic. Each has unique properties that suit specific applications. For instance, stainless steel is resistant to corrosion but can be more expensive. Brass is affordable and versatile, ideal for many common applications.

Data from industry reports show that about 40% of valve failures are due to inappropriate material selection. This highlights the importance of understanding the environment in which the valve operates. For high-pressure applications, stainless steel is often necessary. Conversely, for less demanding situations, plastic may suffice and provide cost savings.

Tip: Always assess the medium flowing through the valve. This can prevent many issues. Another point to consider is the temperature range. High heat can deteriorate plastic, while stainless steel excels under heat stress. Reflect on whether the selected material stands up to the project demands. Avoid the trap of choosing based solely on initial costs.

| Material Type | Temperature Range (°C) | Pressure Rating (MPa) | Corrosion Resistance | Applications |

|---|---|---|---|---|

| Stainless Steel | -50 to 250 | 1.6 | Excellent | Water, Oil, Gas |

| Brass | -40 to 180 | 1.0 | Moderate | Air, Water |

| PVC | 0 to 60 | 0.6 | Good | Chemicals, Water Treatment |

| Ductile Iron | -20 to 150 | 1.6 | Moderate to Good | Heavy Duty Applications |

| Carbon Steel | -29 to 425 | 1.6 | Good | Oil, Gas, Power Plants |

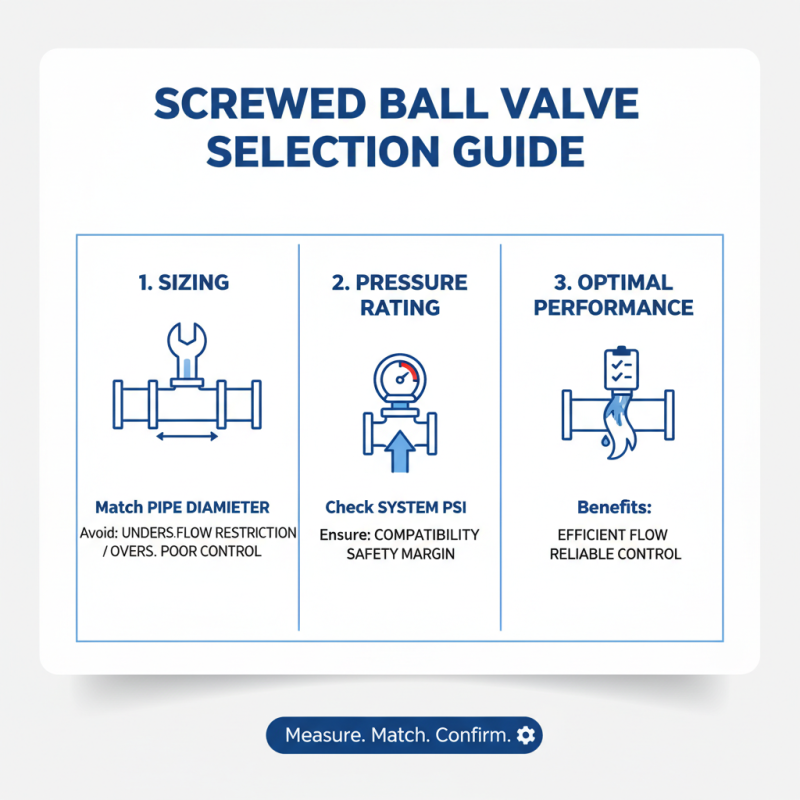

Choosing the right screwed ball valve for your project requires careful consideration of sizing and pressure ratings. A properly sized valve ensures optimal performance. An undersized valve may restrict flow. An oversized valve can lead to poor control. The diameter of the piping system is crucial. Measure it accurately to avoid issues.

Pressure rating is another critical aspect. The valve must withstand the system's operating pressure. Check the maximum pressure in your system. Using a valve with a lower rating can result in failure. This can lead to leaks or catastrophic failures. It's essential to factor in safety margins. They provide extra protection and reliability.

Don't forget to consider the materials used. They affect both performance and durability. For example, corrosion resistance is vital in certain applications. If the valve is not compatible with the media, it will degrade. This ultimately leads to costly replacements. Reflect on your project needs to choose wisely. Making a poor choice can have serious consequences.

When selecting a screwed ball valve, durability is crucial. These valves endure high pressure and temperature. They must withstand wear, corrosion, and thermal cycling. Choose materials wisely to enhance longevity. Stainless steel, for instance, offers excellent resistance. The quality of the seal also matters. If a seal fails, it can lead to leaks and costly repairs.

Regular maintenance extends the life of your valve. Inspect it frequently for signs of wear. Lubricate moving parts to prevent jamming. Cleaning is equally important. Even small debris can impact performance. But maintenance can be overlooked. It’s easy to neglect schedule checks. Yet, doing so can lead to failures. Understand that a small oversight can cause big problems later.

Moreover, installation plays a vital role in durability. Incorrect installation can lead to premature failure. Ensure proper alignment and tight connections. Evaluate your environment, too. If exposed to extreme conditions, additional protective measures may be needed. Assessing these factors will help you make a more informed choice. Sometimes, a quick decision can lead to trouble. A moment of reflection can save you time and money down the road.