-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

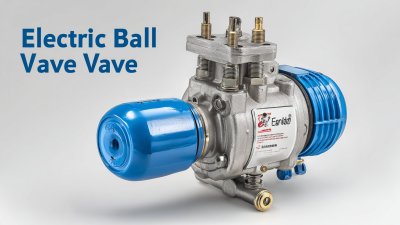

In the rapidly evolving industrial landscape, the selection of the appropriate control mechanisms is crucial for optimizing operations and ensuring efficiency. Among these, the Electric Ball Valve has emerged as a pivotal component, offering precision and reliability in fluid control. According to a market analysis by Grand View Research, the global electric valve market is projected to reach USD 10.23 billion by 2025, expanding at a compound annual growth rate (CAGR) of 6.4%. This surge is largely driven by the increasing demand for automated solutions in various industries, including oil and gas, water management, and chemical processing. Understanding the key factors in selecting an Electric Ball Valve tailored to specific industrial needs can significantly enhance system performance, reduce operational costs, and minimize downtime. This guide aims to provide comprehensive insights into the critical elements to consider when choosing the right Electric Ball Valve for your applications.

When considering electric ball valves for industrial applications, it's essential to understand their fundamental components and functionalities. An electric ball valve operates by using an electric motor to control the rotation of a ball with a bore through it. This design allows for quick and precise regulation of fluid flow, making it ideal for various industries, including oil and gas, food processing, and chemical manufacturing. The choice of materials, such as stainless steel or PVC, can significantly influence durability and performance, especially in corrosive or high-pressure environments.

Different types of electric ball valves are available, including normally open and normally closed configurations. Knowing the specific operation that best suits your needs is crucial. Additionally, features such as automation, feedback systems, and integration capabilities with existing control systems can enhance efficiency and reliability. Therefore, a thorough understanding of these basics will help in selecting the right electric ball valve tailored to your industrial requirements, ensuring optimal performance and longevity in your processes.

This chart compares the flow rates of various sizes of electric ball valves. The data indicates that as the size of the ball valve increases, the flow rate in gallons per minute (GPM) also increases, demonstrating the direct relationship between valve size and performance efficiency.

When selecting the right electric ball valve for industrial applications, several key factors must be taken into account. One of the most critical considerations is the valve's compatibility with the specific fluid and operating conditions in the application. For instance, in industries that handle multiphase flows, it’s essential to evaluate how different valve designs—such as ball, cone, and disk valves—perform under varying flow conditions. A recent numerical and experimental study highlights the differences in two-phase flow characteristics among these valve types, providing valuable insights for engineers when making their selection.

Additionally, the global electric valve market is poised for significant expansion, projected to grow from $4.45 billion in 2024 to an impressive $9.73 billion by 2032. This growth signals the increasing importance of electric valves in critical applications, such as those found in nuclear power plants. As industries increasingly turn to automation and precise control mechanisms, selecting the right electric ball valve will not only enhance operational efficiency but also ensure safety and reliability in demanding environments. Factors like valve material, actuator performance, and maintenance requirements should be meticulously assessed to optimize long-term performance.

When selecting the right electric ball valve for your industrial applications, it's crucial to understand the different types available and their specific functionalities. Electric ball valves come in various designs, including standard, double block and bleed, and high-performance options, each tailored for distinct operational needs. For example, standard electric ball valves are widely used for on/off control, while high-performance valves are designed for applications requiring tight sealing and minimal leakage. Understanding these distinctions can help optimize efficiency and performance in your system.

Tips: When choosing an electric ball valve, consider the medium that will be flowing through the valve, as this impacts the material selection. Non-metallic options may be suitable for corrosive substances, while metallic valves are better for higher pressure systems. Additionally, always check the voltage and power requirements to ensure compatibility with your facility's electrical system.

Another essential factor to consider is the valve’s size and flow capacity. Ensure that the selected valve can handle the required flow rates without causing excessive pressure drops. Consulting the application guidelines and flow charts can provide valuable insights into which type and size of electric ball valve will meet your operational demands best.

When it comes to ensuring the longevity and efficient performance of electric ball valves in industrial settings, regular maintenance is essential. One effective maintenance tip is to conduct routine inspections. Check for any signs of wear, corrosion, or leakage around the valve body and connections. Additionally, ensure that the actuator and positioner are functioning correctly, as any malfunction can lead to operational inefficiencies. Keeping a close eye on these components can prevent small issues from escalating into costly repairs.

Another critical aspect of maintenance is ensuring proper lubrication. Many electric ball valves come with specific lubrication requirements, so it's important to refer to the manufacturer’s guidelines. Regularly lubricating moving parts helps reduce friction and wear, extending the lifespan of the valve. It's also advisable to clean the valve and the surrounding area periodically to remove debris and contaminants that can hinder performance. Ensuring proper sealing and tightness of connections will not only enhance efficiency but will also prevent leaks that can disrupt processes. By following these maintenance tips, operators can maximize the effectiveness of their electric ball valves and minimize unexpected downtimes in industrial applications.

| Specification | Description | Maintenance Tips | Expected Lifespan |

|---|---|---|---|

| Type | Electric Actuated Ball Valve | Regularly inspect for leaks. | 10-15 years |

| Material | Stainless Steel | Keep surfaces clean and free from corrosive substances. | 15-20 years |

| Size | 2-inch | Calibrate the actuator regularly. | 8-12 years |

| Voltage | AC 220V | Ensure correct voltage supply; prevent overvoltage. | 10 years |

| Flow Rate | 50 GPM | Monitor flow rate to ensure optimal performance. | 8-10 years |

Upgrading to electric ball valves in industrial operations offers numerous advantages that can significantly enhance efficiency and control. One of the primary benefits is improved automation. Electric ball valves can be integrated seamlessly into existing control systems, allowing for precise operation and real-time monitoring. This level of automation reduces the need for manual intervention, minimizing the likelihood of human error and streamlining processes. Consequently, operations can run smoother and faster, leading to increased overall productivity.

Another compelling benefit is energy efficiency. Electric ball valves often exhibit superior flow characteristics compared to traditional pneumatic or manual valves. By providing more accurate flow control, they can help reduce energy waste and lower operational costs. Additionally, modern electric ball valves are designed with advanced features such as position feedback and diagnostic capabilities that enhance their overall performance and reliability. This results in reduced maintenance downtime and extended service life, making them a cost-effective solution for many industrial applications.