-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

Choosing the right Electric Ball Valve can be challenging. Industry expert John Doe states, "The key to success is understanding your specific needs." This statement highlights the importance of thorough research. Electric Ball Valves come with varying features. Their applications range from HVAC systems to industrial processes.

When selecting an Electric Ball Valve, consider factors such as voltage, size, and material. Each application can require different specifications. It's vital to reflect on how these variables will impact performance. Many users overlook the importance of compatibility. An incompatible valve can lead to inefficiencies and increased costs.

Additionally, reviewing performance data is crucial. Not all Electric Ball Valves are created equal. Some might not withstand extreme conditions. Reflecting on past mistakes can guide future purchases. Ensure you select a valve that meets both current needs and potential future demands. This investment is critical for achieving optimal results.

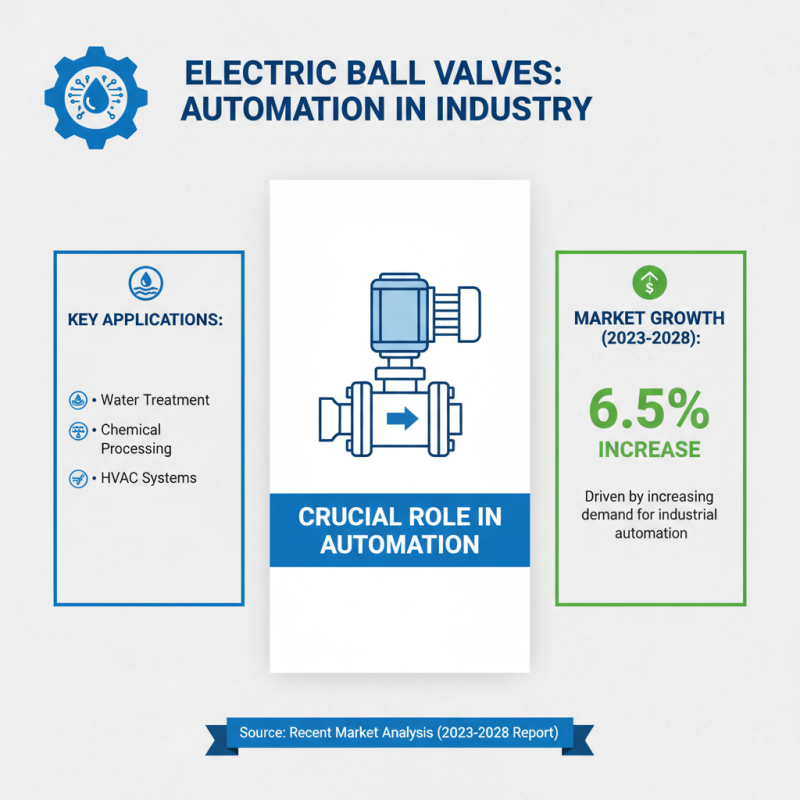

Electric ball valves play a crucial role in various industries. They are widely used in water treatment, chemical processing, and HVAC systems. According to a recent market analysis, the global electric ball valve market is expected to grow by 6.5% from 2023 to 2028. This growth reflects the increasing demand for automation in industrial processes.

When selecting the right electric ball valve, it’s important to consider the specifications. Look for factors such as size, pressure rating, and materials. For example, stainless steel valves may be preferred for corrosive environments. Improper material selection can lead to premature failure, impacting operational efficiency. A study showed that about 30% of valve failures occur due to material incompatibility.

Moreover, understanding the electrical requirements is essential. Some valves require specific voltage and wiring to function correctly. Errors here can result in inefficiencies and safety risks. A survey indicated that 25% of companies reported unexpected downtime due to electrical issues within their valve systems. Ensuring you have the right valve design can save significant time and resources in the long run.

When choosing the right electric ball valve, several key factors come into play. Start with the size and type of your pipeline. An electric ball valve must fit well and work effectively within the system. Check the materials as well. Select valves made from durable materials that suit your fluid type. The operating temperature range is another crucial factor. Ensure the valve can handle your specific conditions.

Tips: Consider the environment where the valve will be installed. Harsh conditions may require extra protection.

Power supply is vital, too. Electric ball valves require reliable power sources. Think about how you will control the valve. Different control options exist. You may need simple on/off control or more advanced modulation. Assess your needs carefully.

Tips: Don’t forget about the installation process. A valve that is hard to install can complicate your project. Check the available space for easy maintenance access.

Electric ball valves are essential in various industries for controlling fluid flow. Understanding the different types is crucial for making a smart choice. There are two main types to consider: 2-way and 3-way electric ball valves.

2-way valves allow flow in one direction. They are ideal for on/off control. These valves are simpler and often more cost-effective. However, they may not fit complex systems requiring directional flow changes. On the other hand, 3-way valves can direct flow between two outlets. This versatility suits mixing or diverting applications. They can be more intricate and expensive.

Material plays a vital role too. Common choices are brass, stainless steel, and plastic. Brass is durable but may corrode in certain environments. Stainless steel is strong and resistant to corrosion. Plastic valves are lightweight but may not handle high pressures well. Consider your application’s conditions carefully. Keep these factors in mind when choosing an electric ball valve.

| Type | Actuator Type | Connection Type | Size Range (inches) | Operating Voltage | Media Types | Temperature Range (°C) |

|---|---|---|---|---|---|---|

| Standard Electric Ball Valve | On/Off | Flanged | 1/2 to 4 | 110-240 VAC | Water, Oil | -20 to 150 |

| Electro-Pneumatic Ball Valve | Modulating | Threaded | 3/4 to 2 | 24 VDC | Air, Gas | -10 to 80 |

| High-Performance Electric Ball Valve | On/Off | Welded | 2 to 12 | 220-480 VAC | Chemical, Slurry | -40 to 200 |

| Fire-Safe Electric Ball Valve | Fail-Safe | Flanged | 1 to 8 | 120 VAC | Hydrocarbons | -20 to 120 |

When selecting the right electric ball valve, evaluating specifications and features is crucial. Different applications require different capabilities. A study by the Valve Manufacturers Association indicates that 75% of valve failures are linked to improper selection. Therefore, understanding your specific needs is essential.

Pay attention to the materials used in the valve. Common materials include brass, stainless steel, and plastic. Each has advantages and disadvantages regarding temperature and pressure resistance. For example, stainless steel offers durability but can be more expensive. Gauge your materials based on the fluid type you will be working with.

Consider the power source as well. Some valves operate on AC power while others use DC. This choice can impact installation and maintenance requirements. Often, a discontinuity in power might lead to performance issues. Remember to think about the control options as well. Integrated automation can enhance efficiency. However, it may increase complexity. The balance between simplicity and sophistication often requires careful thought.

When selecting the right electric ball valve, optimal sizing is crucial. Start by understanding your system's flow requirements. Measure the pipe diameter and flow rate. These factors determine the valve size. A valve that is too small can restrict flow. Conversely, a valve that is too large may not control the flow effectively. This can lead to inefficiencies and potential system failures.

Installation guidelines are equally important. Ensure proper alignment with the piping. Lack of alignment can cause stress on the valve. Additionally, check the mounting orientation. Some valves work best in specific positions. Improper installation can result in leaks or operational issues. It's essential to review the valve's specifications thoroughly. Misjudging these elements can lead to costly repairs down the line. Always consult reliable resources for best practices.

This chart illustrates the flow rates for different sizes of electric ball valves, helping you to understand the optimal size for your application.