-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

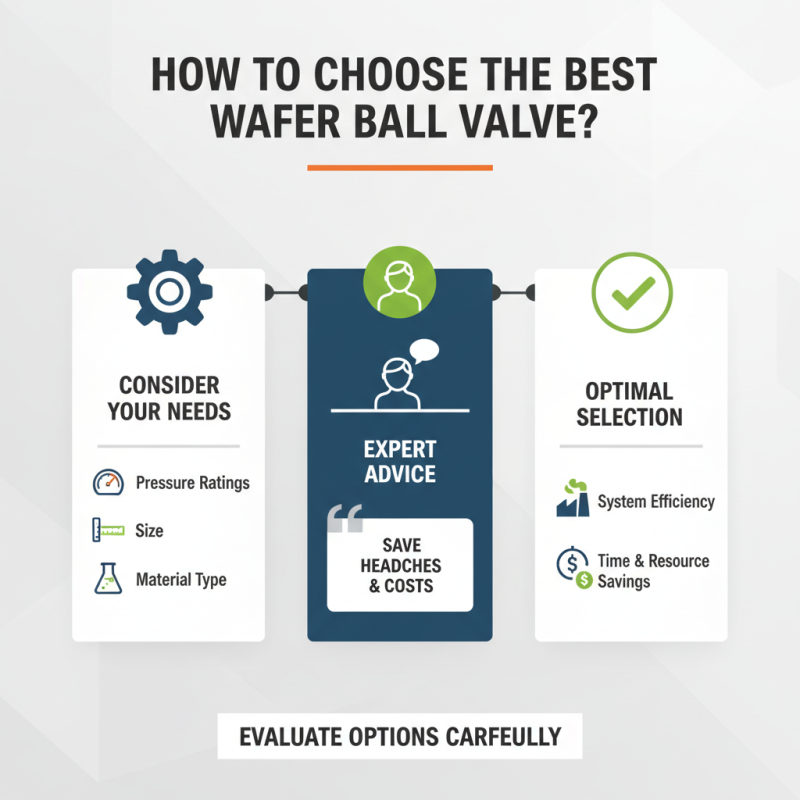

Choosing the best Wafer Ball Valve can be challenging. Expertise from industry professionals can help simplify this process. John Smith, a renowned valve specialist, once said, "The right valve can save headaches and costs in the long run."

When selecting a Wafer Ball Valve, consider your specific requirements. Factors such as pressure ratings, size, and material type play crucial roles. Different applications need different specifications. For instance, high-temperature environments require special materials that withstand heat.

Many overlook these details, which can lead to failures. A Valve that is too small or incompatible can create leaks and downtime. The right Wafer Ball Valve should not only fit your system but also enhance its efficiency. A poor choice can be costly in both time and resources. Take the time to evaluate your options carefully.

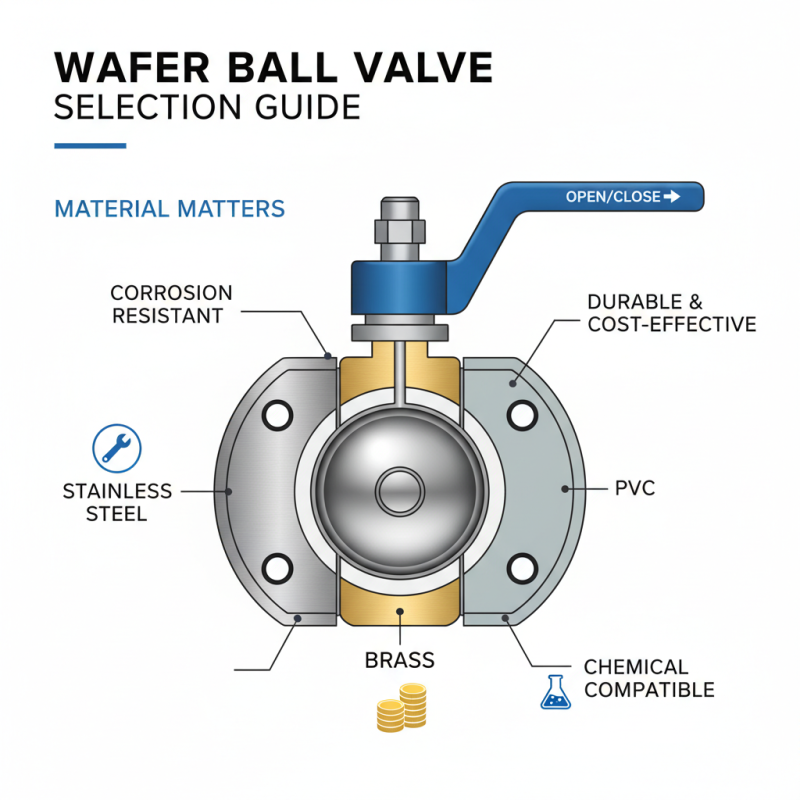

When selecting a wafer ball valve, several factors must be considered. First, the material of the valve is crucial. Common materials include stainless steel, brass, and PVC. Each material has its own advantages. Stainless steel offers excellent corrosion resistance but can be more expensive. Brass is durable and cost-effective, while PVC is lightweight and suitable for chemical applications.

Pressure rating is another key factor. Valves can handle a range of pressure classes. For instance, a valve rated for 150 psi might be insufficient for high-pressure systems. It's essential to match the valve rating with your system's requirements.

**Tip:** Always check the size compatibility. A valve too small may restrict flow, while one that is too large might not seal properly.

Flow characteristics also play a role in valve selection. The flow coefficient (Cv) indicates how efficiently the valve can pass fluid. A higher Cv means less pressure drop and better efficiency in your system.

**Tip:** Don’t overlook installation requirements. Misalignment can lead to performance issues.

Seek guidance from industry reports. An estimated 60% of valve failures come from improper selection or installation. Taking the time to consider these factors can save costs in the long run. Choices made today affect system performance tomorrow. Engaging with a knowledgeable supplier can help clarify your options.

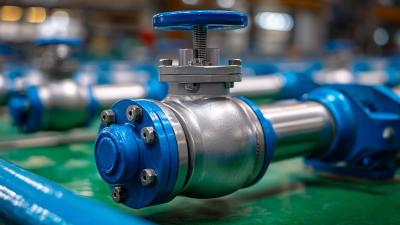

Wafer ball valves come in various types, each designed for specific applications. These valves are compact, lightweight, and offer excellent flow control. The most common types include full port, reduced port, and trunnion-mounted. Full port valves provide an unrestricted flow path, making them suitable for large systems. Reduced port valves have a smaller bore, ideal for smaller flow rates and lower pressure applications.

Trunnion-mounted wafer ball valves are another option. They feature a support system that stabilizes the ball, allowing for higher pressure and larger sizes. These are often used in high-demand applications, like oil and gas. Each type has its own advantages and limitations. It's crucial to consider factors like flow requirements and pressure ratings when choosing.

Understanding your specific needs is key. Each type interacts differently with various fluids. Sometimes, the valve may not perform as expected. Be mindful of installation and maintenance factors too. Small installation errors can lead to significant performance issues. Reflecting on these details often helps in making the right choice.

Selecting the right material for wafer ball valves is crucial. Durability and compatibility influence valve performance. Common materials include stainless steel, carbon steel, and PVC. Each offers distinct advantages. For example, stainless steel resists corrosion but may be more costly.

When choosing a material, consider the application environment. If the valve is used in a corrosive environment, stainless steel is advisable. Carbon steel works well for moderate temperatures. PVC is suitable for chemical applications but not for high-pressure situations.

**Tip:** Analyze your operating temperatures and pressures before making a decision.

Compatibility with the fluid is equally important. Using the wrong material can lead to valve failure. For example, aggressive chemicals can degrade certain plastics. This requires careful assessment during the selection process.

**Tip:** Always conduct a compatibility test with the intended fluid.

While most engineers prefer a specific material, it’s vital to assess all options. Sometimes, a less conventional choice can enhance performance. Don’t overlook suppliers’ recommendations when selecting materials. They often have insights into real-world applications.

This chart shows the durability and compatibility ratings of various materials used in wafer ball valves. The ratings are based on their resistance to corrosion, temperature, and pressure, which are critical factors for valve performance in various applications.

When selecting a wafer ball valve, pressure and temperature ratings are crucial factors. These ratings determine how well the valve can handle specific conditions. Different applications require different ratings. For example, a high-pressure system may need a valve rated for 300 psi or more. Similarly, extreme temperatures can affect valve performance, making it vital to choose one that suits your environment.

Consider the materials used in the valve construction. Some materials can withstand higher temperatures yet may not handle pressure well. A stainless steel valve might perform well under both high heat and pressure, but not all environments warrant such selection. Always assess the specific needs of your application. If there's uncertainty, consult with experts to clarify your choices. It’s easy to overlook these details but doing so can lead to failures or leaks later.

There’s no one-size-fits-all approach. Engineers must weigh various factors when making decisions. A pressure rating that seems sufficient might not be ideal for long-term use. Reflecting on past mistakes can guide better choices. It’s about finding the right balance between pressure and temperature for lasting performance. Take your time and analyze your options carefully. The right valve matters more than you think.

Installation and maintenance of wafer ball valves require careful consideration. When selecting a valve, it’s essential to check compatibility with existing piping systems. Wafer ball valves are known for their compact design, but they may not fit every application. Limited space can lead to installation challenges, especially in cramped areas. A recent industry report indicates that improper installation can reduce valve lifespan by 30%.

Regular maintenance is crucial. Ensure the seals are intact and check for leaks. Neglecting these checks might escalate repair costs. Many facilities overlook the buildup of debris. A survey found that 25% of valve failures are due to insufficient maintenance. Operators should implement routine inspections. Cleaning the valve regularly is useful. However, over-tightening during maintenance could cause damage. Balancing care and caution can be tricky.

Understanding the materials used in wafer ball valves is important too. Specific fluids can cause corrosion if the wrong material is selected. This can lead to premature failures. A study indicates that choosing the right material can improve efficiency by 15%. Yet, many users admit they often choose valves based on price rather than suitability. This can lead to costly errors down the line.