-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

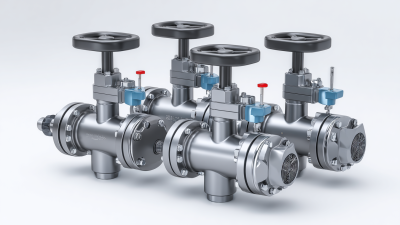

In the demanding world of high-temperature applications, selecting the appropriate High Temperature Ball Valve is crucial for ensuring optimal performance and safety. As noted by industry expert Dr. Emily Carter, a prominent figure in valve technology, “The right High Temperature Ball Valve can significantly impact system efficiency and longevity.” With a myriad of options available, understanding the factors that influence the decision-making process is vital for engineers and procurement specialists alike.

High Temperature Ball Valves are designed to withstand extreme temperature conditions, making them indispensable in various industries, including oil and gas, power generation, and chemical processing. The complexity of choosing the right valve involves consideration of materials, pressure ratings, and compatibility with the specific application. Dr. Carter emphasizes that “a thorough evaluation of application requirements is essential to select a valve that not only meets regulatory standards but also enhances operational efficiency.”

In light of these considerations, this guide aims to equip professionals with the knowledge and tools necessary to make informed decisions when selecting High Temperature Ball Valves. By understanding the critical features and specifications, users can better navigate the marketplace and ensure their systems operate at peak performance under challenging conditions.

High temperature ball valves are essential components in various industries where controlling the flow of fluids at elevated temperatures is critical. These valves are designed to withstand extreme heat, typically above 200°C, making them suitable for applications in oil and gas, chemical processing, and power generation. Understanding the specific requirements of your application, including pressure ratings, temperature ranges, and the nature of the fluids being handled, is crucial when selecting the appropriate valve.

When assessing high temperature ball valves, consider the construction materials, as they must be capable of enduring thermal stress and corrosion. Materials such as stainless steel or specialized alloys are often preferred for their durability and performance under demanding conditions. Moreover, the type of valve seat and sealing technology can significantly influence the valve's efficiency and reliability. It is important to evaluate these factors alongside the operational context, ensuring that the chosen valve aligns with the unique challenges posed by high temperature environments.

When selecting high temperature ball valves for your applications, several key factors must be considered to ensure optimal performance and reliability. First and foremost, understanding the operating temperature range of the valve is crucial. High temperature ball valves are designed to withstand specific temperature limits, and exceeding these can lead to valve failure or leakage. It is important to assess your process conditions to choose a valve that can handle the temperatures it will encounter.

Material selection is another critical aspect to consider. The valve body, seats, and seals must be made from materials that can withstand not only high temperatures but also the specific chemical environment of your application. For instance, materials like stainless steel or special alloys may be necessary if corrosive substances are involved. Additionally, the design of the valve should allow for thermal expansion without compromising the valve's integrity.

Tips: Always review the pressure ratings alongside temperature limits to ensure compatibility, as high temperatures can also affect the pressure capabilities of the valve. Furthermore, consider the ease of maintenance and installation when selecting your valve, as this can impact downtime and operational efficiency. Lastly, consult with your engineering team or valve specialist to ensure the chosen valve meets all operational and safety requirements for your specific application.

When selecting high-temperature ball valves, the materials and construction are critical factors that directly influence performance and reliability in demanding applications. High-temperature ball valves are typically subjected to temperatures exceeding 200°C (392°F), and the choice of materials used in their manufacturing is essential. Common materials for high-temperature applications include stainless steel, exotic alloys, and specially formulated plastics that can withstand prolonged exposure to heat without losing integrity. According to a report by the Valve Manufacturers Association, approximately 60% of high-temperature valve failures are attributed to material degradation, making it imperative to choose high-quality materials.

In addition to material selection, the construction of the valve plays a significant role in its ability to perform under high temperatures. Many high-temperature ball valves feature reinforced seats and seals designed for thermal expansion and contraction while maintaining a tight seal. For instance, the American Society of Mechanical Engineers (ASME) specifies stringent requirements for valve construction in high-temperature environments, ensuring they can handle stress without compromising safety or functionality. Valves manufactured with bolted connections or welded constructions often provide enhanced durability, enabling them to perform effectively in industries such as oil and gas, power generation, and chemical processing, where extreme temperatures are common.

| Material | Temperature Resistance (°C) | Pressure Rating (PSI) | Construction Type | Applications |

|---|---|---|---|---|

| Stainless Steel | -40 to 150 | 1500 | Full Port | Oil & Gas, Water Treatment |

| Carbon Steel | -29 to 200 | 2000 | Reduced Port | Power Generation, Process Industries |

| Creeper Alloy | -40 to 300 | 3000 | Trunnion Mounted | Chemical Processing, High Pressure Systems |

| PTFE Lined | -40 to 260 | 1500 | Lined Valve | Pharmaceuticals, Food Processing |

When selecting a high temperature ball valve for specific applications, understanding sizing and pressure ratings is paramount for ensuring optimal performance. High temperature ball valves are critical in various industries, including oil and gas, petrochemical, and power generation, where media handling demands reliable and durable equipment. According to the "Valve Sizing and Selection Guide" published by the Valve Manufacturers Association, achieving the correct size is essential to maintain the required flow rate while preventing excessive pressure drop.

Typically, high temperature ball valves are rated for temperatures reaching up to 600°F (316°C) and more. For instance, a recent technical report from the American Society of Mechanical Engineers (ASME) suggests that the pressure rating should align with both the valve body material and the application's design requirements. Common materials include stainless steel and high-performance alloys, which offer enhanced resistance to high temperatures and pressures. Pressure ratings, often categorized as ANSI classes (e.g., Class 150, Class 300, etc.), indicate the maximum pressure a valve can withstand while operating safely under specified conditions.

Moreover, proper sizing involves not only the diameter of the valve but also consideration of the piping layout and medium viscosity. As illustrated in a study published in the Journal of Pressure Vessel Technology, factors like fluid type and flow characteristics influence valve selection and performance. Engineers are urged to perform detailed calculations and modeling to select a valve that will not only ensure efficiency but also prolong the longevity of the system while minimizing maintenance needs.

High temperature ball valves are essential components in various industrial applications, particularly in processes involving extreme temperature conditions. The maintenance and lifespan of these valves significantly depend on their material composition, design quality, and the operational environment. According to a recent industry report, improper maintenance can lead to a reduction in the valve’s lifespan by up to 30%. Regular checks for wear and tear, proper lubrication, and timely replacement of seals can mitigate such risks and ensure the valves function efficiently over time.

Tips for ensuring the longevity of high temperature ball valves include routinely monitoring the temperature and pressure conditions they are subjected to. Excessive exposure to fluctuating temperatures can strain the valve materials, leading to premature failure. Additionally, consider implementing a predictive maintenance strategy by utilizing data analytics to schedule inspection and maintenance proactively. A study indicated that companies adopting predictive maintenance could increase equipment uptime by 20% and extend the operational lifespan of critical components significantly.

Furthermore, selecting the right materials for high temperature applications is crucial. Valves made with advanced alloys or polymeric materials specifically designed for high-temperature resistance tend to offer better performance and durability. Always consult with industry guidelines and technical data sheets to ascertain the appropriate specifications for your specific application to prevent costly downtime and repairs.