-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

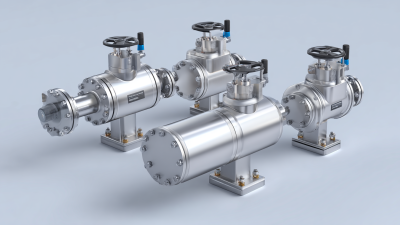

When it comes to industrial applications, selecting the right equipment can significantly impact operational efficiency and safety. One critical component often overlooked is the Double Seated Ball Valve. This type of valve is specifically designed to handle high-pressure conditions while providing superior sealing capabilities, making it an ideal choice for a variety of processes. However, with numerous options available in the market, choosing the appropriate Double Seated Ball Valve for your specific industrial needs can be a daunting task. In this blog, we will explore essential tips and best practices to help you make an informed decision, ensuring that your selection not only meets regulatory standards but also enhances the overall performance of your systems. Whether you are dealing with corrosive fluids, high-temperatures, or varying pressures, understanding the key features and functionalities of Double Seated Ball Valves is crucial for optimizing your industrial operations.

Understanding the basics of double seated ball valves is crucial for ensuring optimal performance in industrial applications. These valves are designed to provide efficient flow control and tight sealing under varying pressure conditions, making them suitable for a wide range of environments. In many industries, including oil and gas, chemical processing, and water treatment, the correct selection of a double seated ball valve can impact both operational efficiency and system safety. Studies indicate that using high-quality valves can reduce maintenance costs by up to 30%, highlighting their importance in industrial settings.

**Tip:** When selecting a double seated ball valve, assess key factors such as size, pressure rating, and the nature of the media being handled. Choosing the right materials is also critical; for example, stainless steel is often preferred for its corrosion resistance in demanding environments.

Additionally, understanding valve positioning and actuator compatibility is vital. For instance, advanced valve positioners have demonstrated an ability to enhance the accuracy and reliability of valve operations, leading to improved overall system performance. Investing in technologies that facilitate precise control can yield significant returns, potentially enhancing energy efficiency and reducing operational downtime.

**Tip:** Always consider the lifecycle costs of the valve, including installation, maintenance, and potential replacement. A valve that may be more expensive initially can ultimately prove to be more cost-effective in the long run due to lower maintenance needs and higher durability.

When selecting a double seated ball valve for industrial applications, several key factors must be considered to ensure optimal performance and longevity. First and foremost, the operating conditions, such as temperature and pressure, should align with the valve’s specifications. Understanding the environment in which the valve will be used helps to determine the appropriate materials and components. For example, high-temperature or corrosive substances may require valves made from specialty alloys or coatings to prevent degradation.

Another crucial aspect is the valve’s sizing and flow characteristics. An improperly sized valve can lead to flow limitations or excessive turbulence, affecting overall system efficiency. It's important to calculate the required flow rate and match it with the valve's Kv or Cv values. Additionally, assess the connection type and installation requirements to ensure compatibility with existing piping systems. Incorporating these considerations will facilitate a smooth operation and enhance the reliability of the double seated ball valve in your industrial setup.

When selecting a double seated ball valve for industrial applications, the choice of material is crucial to ensuring durability and performance. Common materials include stainless steel, carbon steel, plastic, and brass, each offering distinct advantages depending on the specific environmental conditions. Stainless steel, for example, is known for its corrosion resistance and strength, making it ideal for high-pressure and high-temperature applications. Its ability to withstand harsh chemicals and environments significantly extends the lifespan of the valve.

On the other hand, plastic valves can provide a lightweight alternative with excellent resistance to corrosive substances, ideal for industries like chemical processing where aggressive fluids are common. Carbon steel valves, enhanced with coatings or linings, can handle a wide range of fluids at lower costs, while brass valves offer good thermal conductivity and resistance, making them suitable for heating systems.

When choosing the right material, consider not just the immediate application but also the long-term demands, as the right choice will lead to improved efficiency, reduced maintenance costs, and enhanced system reliability.

When selecting the right double seated ball valve for industrial applications,

understanding pressure and temperature ratings is crucial.

According to the American Society of Mechanical Engineers (ASME),

many industrial processes operate under high pressure and temperature conditions,

which directly impact valve performance. For example, a valve rated at

150 psi might suffice in low-pressure systems,

but for higher demands, a valve with a rating of up to

600 psi or more could be necessary to ensure safety and functionality.

Tip: Always consult the manufacturer's specifications for temperature ratings,

as materials can influence performance. For instance, stainless steel valves may function efficiently

at temperatures up to 450°F, while other alloys, like Inconel,

can withstand even greater extremes, making them suitable for the chemical processing industry.

When evaluating your specific requirements, consider the fluid being handled.

Different materials react differently to various chemicals, leading to potential leakage or valve failure.

For instance, valves that need to operate in high-temperature steam applications should be rated accordingly.

Real-world studies indicate that 40% of valve failures occur due to improper

temperature ratings, underscoring the importance of precise selection.

Tip: Utilize pressure-temperature charts available from valve manufacturers

to cross-reference your operating conditions and prevent costly breakdowns.

When it comes to the installation of double seated ball valves, proper alignment is crucial to ensure optimal performance and longevity. Begin by selecting an appropriate inlet and outlet orientation based on your system's design. Ensure that the valve is installed in a way that allows for unobstructed flow and easy access for future maintenance. It's also important to utilize the correct mounting supports to accommodate the weight of the valve and prevent any undue stress on the piping system.

Maintenance of double seated ball valves should be approached with routine inspections and proactive measures. Regularly check for leaks and ensure that the valve seat is free from debris or corrosion that can compromise its integrity. It's advisable to operate the valve fully through its range occasionally to keep the seating surfaces clean. Additionally, lubrication of the valve stem can significantly enhance its operation. Implementing these best practices will not only extend the life of your double seated ball valves but also enhance the overall efficiency of your industrial processes.

This chart illustrates the performance metrics and maintenance frequencies for double seated ball valves over a period of one year. The data reflects various operational parameters that are critical for ensuring optimal functionality and longevity of the valves.