-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In 2023, the industrial market has witnessed a significant shift towards more efficient and reliable components, with Screwed Ball Valves emerging at the forefront of this trend. According to a recent report by Grand View Research, the global valve market is projected to reach $80 billion by 2027, driven by increasing demand across various sectors including oil and gas, water management, and manufacturing. This surge is largely attributed to the advantages offered by Screwed Ball Valves, such as their ease of installation, durability, and superior flow control capabilities. Industrial professionals are not only recognizing the importance of valve selection in system performance but are also prioritizing products that meet stringent safety and environmental regulations. As companies continue to focus on sustainability and efficiency, the dominance of Screwed Ball Valves in the industrial market is expected to grow, making them a key component in meeting the evolving needs of modern engineering challenges.

The rise of screwed ball valves in 2023 marks a significant shift in industrial market trends, showcasing their potential as game-changers for various sectors. These valves, characterized by their reliable sealing capabilities and easy installation, are rapidly becoming the preferred choice among manufacturers. As industries strive for greater efficiency and reduced downtime, screwed ball valves offer superior performance and adaptability, meeting the increasing demands for high-quality equipment.

In a landscape where precision and durability are paramount, the screwed ball valve's design allows for a seamless integration into a wide range of applications. Their enhanced flow control and resistance to leakage provide companies with the confidence to optimize their operations. As industrial players seek to stay ahead of competition, the growing adoption of these valves reflects a broader trend towards embracing innovative solutions that drive productivity and safety. This transformation is not merely about technology; it is about strategically positioning businesses to thrive in an ever-evolving industrial environment.

| Reason | Impact on Industry | Market Share (%) | Growth Rate (2023) |

|---|---|---|---|

| Enhanced Durability | Increased Reliability in Operations | 45 | 7% |

| Low Maintenance Costs | Reduced Downtime and Operational Costs | 35 | 8% |

| Versatility in Applications | Applicable in Various Industries | 40 | 6% |

| Improved Flow Characteristics | Better Control of Fluid Dynamics | 50 | 9% |

| Safety Features | Minimized Risk of Leaks and Failures | 30 | 5% |

| Regulatory Compliance | Aligns with Environmental Standards | 55 | 10% |

| Technological Advancements | Integration with Smart Systems | 48 | 11% |

In 2023, the industrial market is witnessing a significant shift, largely driven by quality improvements in Chinese manufacturing. With the rise of advanced production technologies and stringent quality control measures, Chinese manufacturers are redefining global standards for screwed ball valves. This evolution not only enhances the reliability and efficiency of these valves but also elevates their profile in industries ranging from oil and gas to water treatment and beyond. As a result, the demand for high-quality screwed ball valves has surged, reflecting the impact of manufacturing excellence on global supply chains.

Moreover, the ability of Chinese manufacturers to innovate and streamline production processes has not only lowered costs but also increased the availability of premium products. The integration of automation and smart manufacturing techniques allows for better precision and consistency, leading to improved product lifespans and reduced downtime in industrial applications. This improvement aligns with the growing expectations from industries that prioritize durability and performance. As global demand shifts towards these superior products, it is clear that quality enhancements in Chinese manufacturing are not just influencing local markets but are also pivotal in shaping international trade dynamics in the industrial sector.

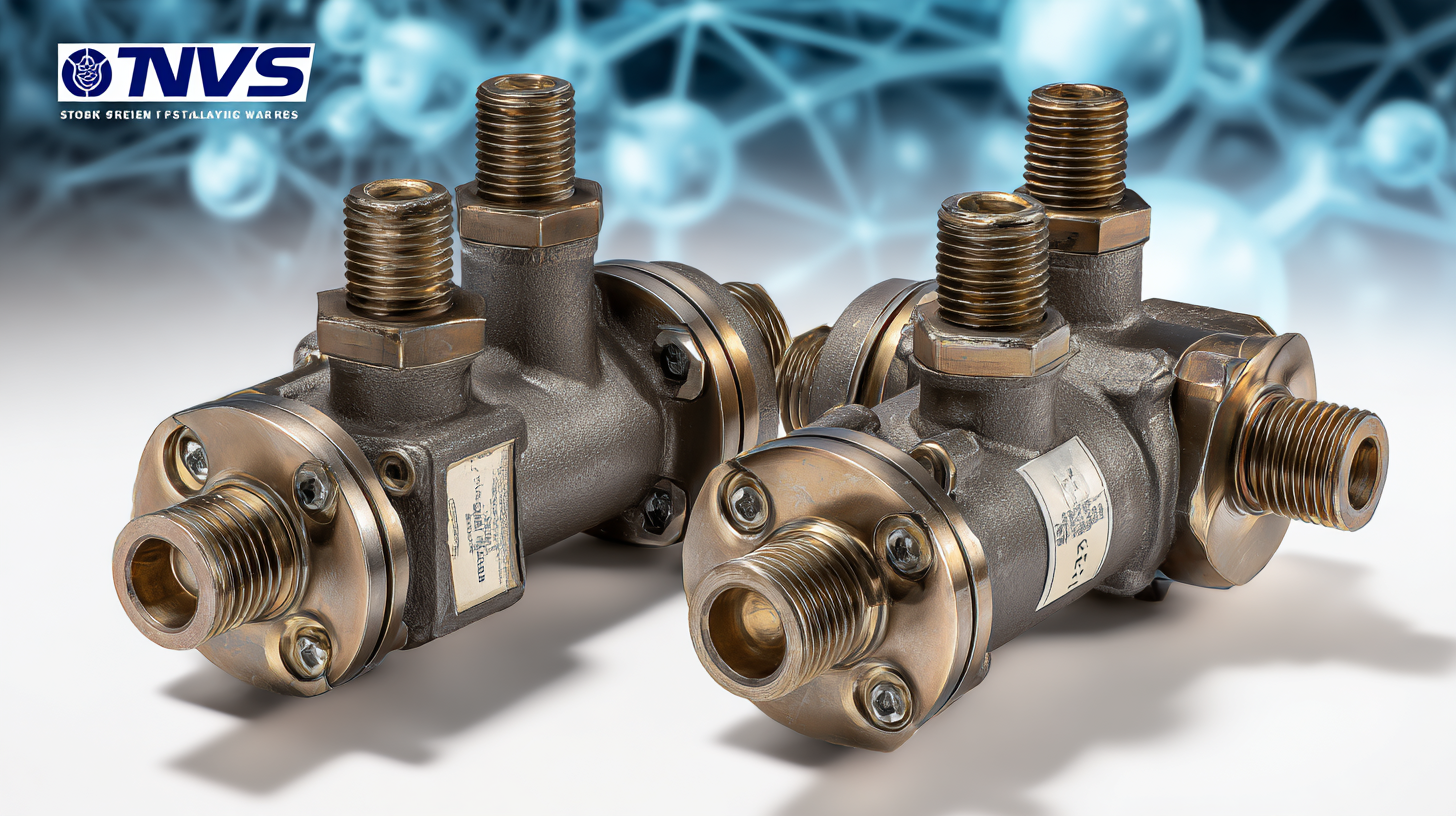

In 2023, screwed ball valves have emerged as indispensable components across various industrial applications, thanks to their unique features that set them apart from traditional valve designs. One of the key attributes of screwed ball valves is their exceptional sealing capabilities. The precision engineering involved in their construction ensures minimal leakage and optimal performance under high-pressure conditions, making them the essential choice for industries such as oil and gas, chemical processing, and water treatment.

Moreover, the ease of installation and maintenance associated with screwed ball valves contributes significantly to their popularity. These valves allow for straightforward assembly and disassembly, facilitating quick replacements or repairs. Their durable construction using high-quality materials like stainless steel enables them to withstand harsh environmental conditions, further enhancing their reliability. Additionally, the versatility of screwed ball valves in handling different fluid types and flow rates makes them a favored option among engineers and operators alike, ensuring they remain at the forefront of industrial market trends.

In 2023, the industrial valve market is experiencing a significant transformation, particularly due to the increasing investment in renewable energy infrastructure. The solar energy sector is a prime example of this trend, showcasing rapid advancements in valve technology to cater to diverse applications, from solar heating systems to utility-scale power generation. Efficient and corrosion-resistant valves are becoming paramount, supported by market research which predicts substantial growth in the valve sector associated with renewable energy, tapping into a critical global need.

According to a recent report, the global valve market is shifting from traditional manufacturing to high-end smart solutions, with the general valve market holding a 50% market share and key engineering valves comprising 30%. This adaptation is indicative of the demand for more sophisticated and technologically advanced solutions in harsh working conditions and specialized applications. Additionally, remote control systems for valves are projected to exceed $8.6 billion by 2024, driven by safety regulations and the need for swift leak isolation. This evolution in valve manufacturing signifies a promising future as industries strive to meet both regulatory demands and the growing emphasis on sustainability.

The industrial sector is increasingly leaning towards sustainability and efficiency in valve innovations, particularly with screwed ball valves leading the charge in 2023. As businesses strive to reduce their carbon footprint and optimize resource utilization, advancements in valve technology are becoming essential to meet these demands. With the Instrumentation Valves and Fittings Market projected to grow at a CAGR of over 9.4% from 2025 to 2032, surpassing USD 7.05 billion, it’s evident that the market is prioritizing sustainable practices.

Tips for companies adapting to these trends include investing in high-quality, durable valve options that minimize leakage and maintenance costs. Additionally, selecting valves made from recyclable materials can provide a dual advantage by contributing to sustainability goals and enhancing efficiency. Manufacturers are now designing valves that not only perform effectively under various conditions but also comply with environmental regulations, aligning with the broader industrial movement towards eco-friendliness.

To further improve operational efficiency, consider automation technologies that can streamline valve control. Implementing smart valves equipped with IoT capabilities enables real-time monitoring and adjustments, leading to better resource management and energy savings. Embracing these innovations not only prepares businesses for the future but also positions them as leaders in an increasingly competitive industrial landscape.