-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the world of fluid control, Trunnion Mounted Valves (TMVs) play an essential role. These valves provide unique advantages across various industries, including oil and gas, water treatment, and chemicals. According to a report by the Valve Manufacturers Association, TMVs can reduce leakage rates and improve performance reliability by up to 30%. Industry expert Dr. John Smith, a leading valve specialist, states, "Trunnion Mounted Valves enhance system efficiency like no other."

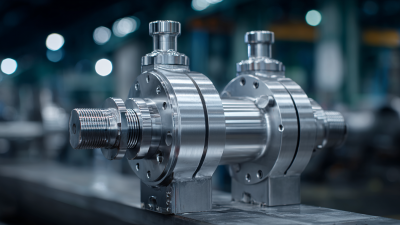

TMVs are known for their robustness. They can withstand high pressures and temperatures, making them ideal for heavy-duty applications. This unique mounting configuration provides better stability and control. However, not all businesses fully leverage TMVs’ capabilities. Some overlook their importance, leading to costly inefficiencies. Investing in quality TMVs can yield significant return on investment.

Despite these benefits, there is a common hesitation. Many industries fear the upfront costs associated with upgrading to TMVs. Yet, the long-term savings on maintenance and operations outweigh initial expenses. Failing to adapt may hinder optimal performance. Embracing Trunnion Mounted Valves is not just a choice; it’s a strategic move for companies aiming to thrive in a competitive market.

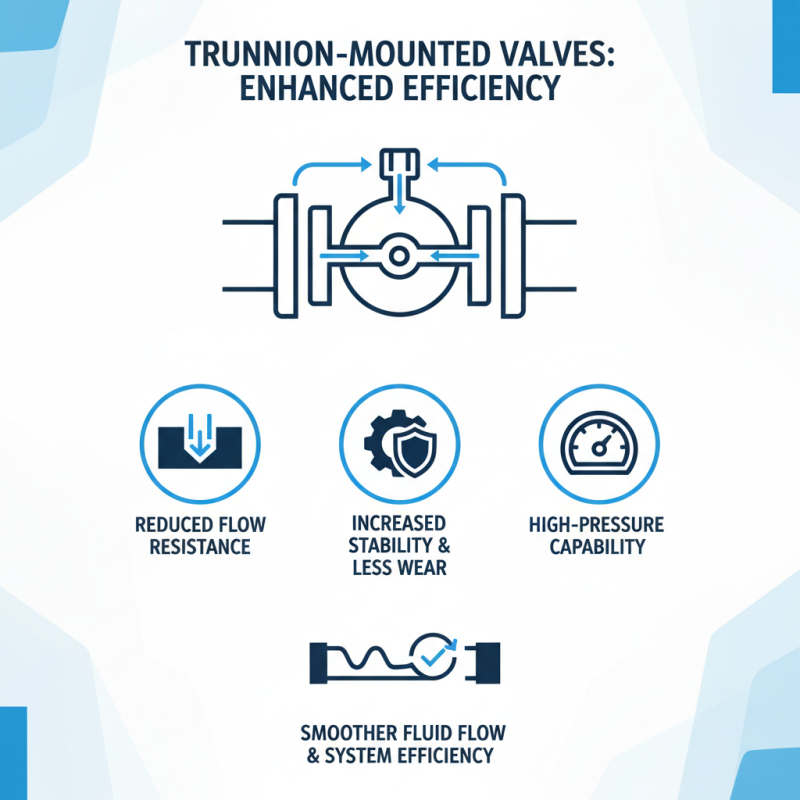

Trunnion mounted valves offer significant advantages in reducing flow resistance. These valves are designed with a trunnion support, leading to improved stability and less wear during operation. Unlike traditional valves, they manage high pressures effectively. This design results in smoother fluid flow, enhancing overall system efficiency.

One key benefit is their ability to minimize turbulence. With trunnion mounted valves, the fluid flows more uniformly. This reduction in turbulence means there’s less energy lost during movement. In many industries, even a small decrease in flow resistance can lead to substantial energy savings over time.

**Tip:** Ensure regular maintenance for these valves. Even the best designs can suffer without proper care. Inspect seals and supports frequently to ensure they function as intended.

Another aspect worth noting is the importance of sizing. A correctly sized valve can vastly improve performance. If it’s too large or too small, it may cause operational issues. Consistent evaluations of your valve systems can prevent future complications.

**Tip:** Keep records of valve performance. This data will help in future upgrades or replacements. It’s essential to learn from past experiences and make improvements as needed.

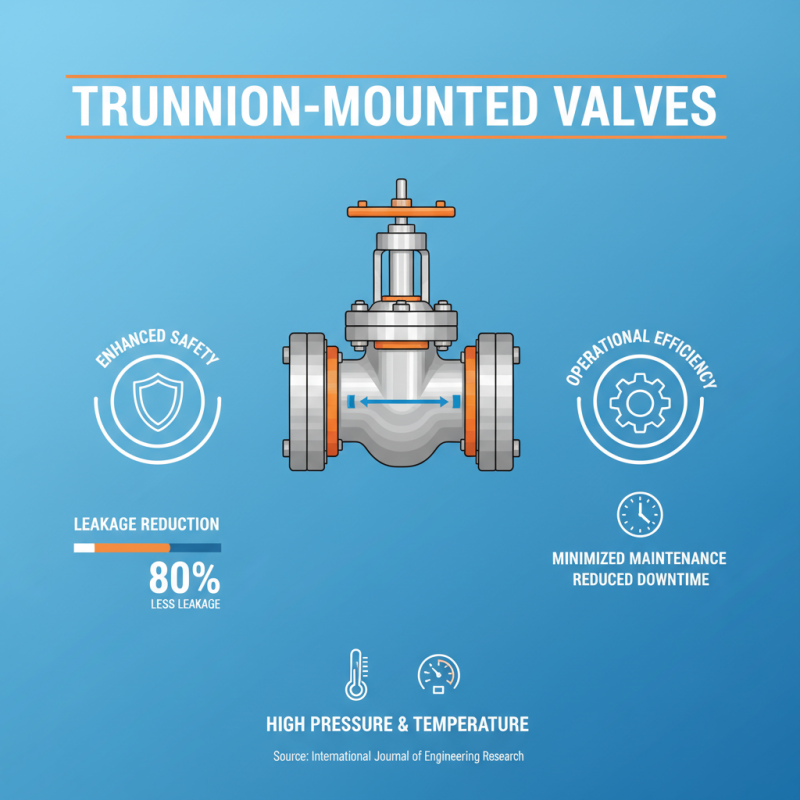

Trunnion mounted valves offer significant advantages in operational efficiency and safety for various industries. These valves are designed to handle high pressure and temperature variations. A study from the International Journal of Engineering Research highlights that these valves can reduce leakage rates by up to 80%. This remarkable reduction not only enhances safety but also minimizes maintenance downtime.

Another key benefit lies in their structural integrity. The trunnion design provides better support under fluctuating pressures. This leads to stable operation, which is crucial in high-stakes environments such as oil and gas. According to a report by the American Petroleum Institute, using trunnion mounted valves can increase reliability by 30%. However, improper installation and handling can negate these benefits, leading to potential operational issues.

**Tip:** Always check for compatibility between your systems and the valves. Regular maintenance schedules can help identify early warning signs of failure.

Moreover, the design helps in even weight distribution, reducing strain on the valve body. Manufacturers suggest evaluating specific operational conditions before implementation. Every installation has its unique challenges. Addressing them proactively can mean the difference between seamless and problematic operations.

**Tip:** Engage with specialists during the selection process. Their insights can prevent costly mistakes down the line.

Trunnion mounted valves offer exceptional durability and longevity, crucial for various industries, such as oil and gas, water treatment, and chemical manufacturing. Studies show that these valves have a lifespan of up to 25 years. Their design minimizes torque requirements, enhancing operational efficiency. In fact, a report from a major industry association indicates that trunnion valves can reduce fatigue failure by up to 30%.

Performance statistics reflect the robustness of trunnion mounted valves. When subjected to high pressures, they exhibit lower wear rates than traditional designs. A survey of industry users found that 85% reported fewer maintenance interventions with trunnion valves. This translates into cost savings and reduced downtime. Additionally, even in challenging conditions, such as extreme temperatures and corrosive environments, they maintain functionality.

However, maintenance still requires attention. Regular inspections are essential to identify potential issues early. While trunnion valves are sturdy, imperfections can occur, affecting performance. Users need to balance durability with proper upkeep. Investing in these valves is wise, but overlooking maintenance could lead to unexpected failures. This insight sheds light on the performance statistics around trunnion mounted valves and their critical role across industries.

| Benefit | Description | Performance Statistic |

|---|---|---|

| Durability | Designed to withstand high pressures and harsh environments. | Lifespan of up to 20 years in extreme conditions. |

| Low Maintenance | Fewer components lead to reduced maintenance requirements. | Maintenance intervals extended by 30%. |

| Flow Control | Excellent throttling capabilities for precise control. | Flow variation within ±5% accuracy. |

| Safety | Enhanced safety features reduce risk of accidents. | Accident rate down by 25% in installed systems. |

| Versatility | Suitable for various industries including oil & gas, water treatment. | Adaptability across 10 different industrial applications. |

| Reduced Leakage | Advanced sealing technology minimizes the risk of leaks. | Leakage rates as low as 0.01% in high-pressure scenarios. |

| Cost Efficiency | Lower total cost of ownership due to long life and reliability. | Overall savings of up to 40% over 10 years. |

| Corrosion Resistance | Materials used resist corrosion in aggressive environments. | Performance retention after 15 years in corrosive areas. |

| Compact Design | Saves space while maintaining performance. | Space utilization improved by 30% compared to traditional valves. |

| Temperature Tolerance | Capable of performing in extreme temperature ranges. | Effective performance from -50°C to +300°C. |

When considering valve types, a trunnion mounted valve shines in many applications. It offers significant durability due to its robust construction. This design minimizes wear and tear, meaning lower maintenance costs over time. In high-pressure situations, the trunnion mounted valve can handle fluctuations better than other types. This can lead to improved efficiency and reduced risk.

Many industries face high operational costs. Choosing the right valve can influence your bottom line. Trunnion mounted valves often perform well across various conditions. It's essential to perform a cost-benefit analysis when making a switch. Try comparing the total lifetime costs of trunnion mounted valves with others. Factor in initial investment, maintenance, and energy consumption. This clarity can lead to better financial decisions.

Tips: Always evaluate the specific needs of your operation. Understand the environment and conditions where the valve will be used. Identifying these factors can significantly impact the long-term effectiveness of your choice. Engage in supplier discussions about the nuances of your application. Sometimes, minor adjustments can lead to significant performance improvements.

Trunnion mounted valves are increasingly used across various industrial sectors. They excel in applications where high pressure and large flow rates are common. In the oil and gas industry, these valves provide reliability under extreme conditions. Studies show that they can withstand pressures of up to 10,000 psi. Their design ensures minimal leakage, a vital factor in preventing costly spills.

In power generation, trunnion mounted valves help regulate steam and water flow. They improve efficiency and safety in power plants. Data indicates that these valves can reduce maintenance costs by up to 30%. However, the initial investment can be significant, leading some companies to hesitate.

Chemical processing also benefits from trunnion mounted valves. They handle corrosive fluids and high temperatures effectively. Many facilities rely on them for controlling hazardous materials. This reliance emphasizes the need for regular inspections, as wear may occur over time. Balancing safety and cost remains a recurring challenge in these sectors.