-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the realm of industrial valves, the choice of the right component can vastly influence the efficiency and safety of operations. Among the myriad of options available, the Screwed End Ball Valve stands out as a preferred choice for many industries due to its unique design and functional advantages. This article delves into the key benefits that make Screwed End Ball Valves a go-to solution for various applications, shedding light on their reliability, ease of installation, and cost-effectiveness. By exploring these advantages, we aim to provide insights that not only highlight the significance of this valve type but also assist industry professionals in making informed decisions.

As the market evolves and demands for high-performance products increase, understanding the value of Screwed End Ball Valves becomes essential. Their ability to handle different pressures and flow rates ensures that they meet diverse operational requirements, making them a versatile component for both simple and complex systems. In the following sections, we will outline five key benefits of using Screwed End Ball Valves and offer valuable industry insights that will further contextualize their importance within contemporary engineering and manufacturing practices.

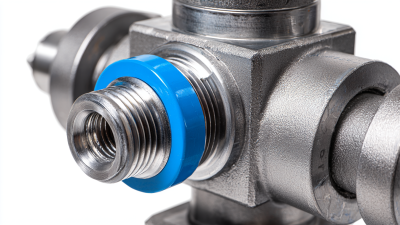

Screwed end ball valves are becoming increasingly popular in various industrial applications due to their distinct advantages. One of the primary benefits is their ease of installation. The screwed end design allows for straightforward connection to pipelines without requiring extensive modifications. This not only speeds up the installation process but also reduces labor costs, making it a practical choice for industries looking to enhance efficiency.

Another significant advantage is their robust sealing capability. Screwed end ball valves are engineered to provide tight seals, which prevents leaks and ensures the reliable operation of fluid systems. This characteristic is particularly beneficial in sectors like oil and gas, chemical processing, and water treatment, where maintaining integrity in fluid handling is critical. Additionally, these valves are designed to withstand high pressures and temperatures, further solidifying their position as a suitable option for demanding environments.

Overall, the combination of easy installation and superior sealing makes screwed end ball valves a favored choice in contemporary industrial settings.

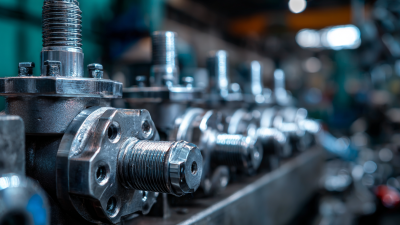

Screwed end ball valves have gained popularity in various industries due to their ability to enhance operational efficiency significantly. According to a recent industry report by Global Market Insights, the demand for ball valves is projected to grow at a CAGR of 6.8% from 2023 to 2030, driven by their reliable performance in critical applications. One of the primary reasons for this growth is the exceptional tightness and durability these valves offer, which are essential for maintaining system integrity and reducing leakages. Studies indicate that valves with screwed end designs can reduce installation time and costs by up to 20%, allowing industries to boost their productivity.

Performance metrics also reveal that screwed end ball valves can optimize flow control and minimize pressure losses, further enhancing plant performance. A comprehensive analysis by the Valves and Actuators Manufacturers Association (VAMA) reported that the use of high-quality screwed end ball valves led to a 15% increase in energy efficiency for fluid handling systems across various sectors. Additionally, their robust construction allows them to handle high pressures and temperatures, catering to the unique requirements of industries such as oil and gas, chemical processing, and water treatment. As companies increasingly seek innovative solutions to improve operational efficiency, screwed end ball valves stand out as a key component in achieving those goals.

This bar chart illustrates the operational efficiency of screwed end ball valves across various performance metrics, showcasing their advantages in the industry.

The global market for screwed end ball valves is poised for significant growth, driven by the increasing demand for pneumatic components. According to industry reports, the global pneumatic components market size is expected to surge from $14.81 billion in 2025 to an impressive $21.58 billion by 2032. This growth highlights the vibrant opportunities within the valve manufacturing sector, as these components play a crucial role in the efficient operation of various systems, from industrial applications to residential plumbing.

As the industry evolves, manufacturers must adapt to the rising trends associated with pneumatic technology. Tips for selecting the right screwed end ball valves include considering the compatibility with the specific application, ensuring quality certifications, and evaluating the valve's performance ratings. Additionally, the integration of advanced materials and technologies can enhance durability and reliability, making these valves even more appealing to end-users.

Investors and industry stakeholders should also pay attention to the rapidly expanding adsorbent glass mat (AGM) battery market, which has seen significant growth attributed to its suitability for start-stop vehicle technology. As sectors like automotive and manufacturing increasingly rely on pneumatic solutions, the strategic positioning and innovation in valve technology will be essential for capitalizing on the market's upward trajectory.

| Benefit | Description | Industry Insight | Projected Market Growth by 2025 |

|---|---|---|---|

| Durability | Made with high-quality materials, offering longer lifespan and reliability. | Increasing demand in corrosive environments drives material innovation. | 5% CAGR |

| Ease of Installation | Screwed end design allows for straightforward installation without specialized tools. | Growing preference for DIY installations in residential projects. | 4.5% CAGR |

| Cost-Effectiveness | Reduced labor costs due to simpler installation processes. | Market trends shifting towards budget-friendly solutions. | 6% CAGR |

| Versatility | Applicable across a wide range of industries including oil & gas, water supply, and HVAC. | Increased application in emerging industries boosts versatility. | 7% CAGR |

| Low Maintenance | Requires minimal maintenance due to simple design and fewer moving parts. | Rising demand for low-maintenance solutions in industrial applications. | 5.5% CAGR |

When selecting screwed end ball valves, material considerations play a crucial role in ensuring performance and longevity. The choice of composition impacts not only the valve's resistance to pressure and temperature but also its compatibility with the fluids it will control. Stainless steel, brass, and PVC are popular materials, with stainless steel being favored in applications requiring high durability and corrosion resistance, particularly in the oil and gas sector.

Tips for selecting the right material include assessing the operating environment and the chemical properties of the fluid. For instance, if the valve will be exposed to harsh chemicals or extreme temperatures, opting for high-grade materials can prevent premature failure. Additionally, consideration of the valve’s pressure rating is vital to ensure safe operation under fluctuating conditions, a characteristic common in cyclical industries like oil and gas.

As trends in the energy market shift, staying informed about material innovations can provide a competitive edge. Understanding your specific needs and aligning them with the latest advancements can optimize the performance of your screwed end ball valves, resulting in improved efficiency and reliability in your systems.

Screwed end ball valves are becoming increasingly popular in various manufacturing sectors due to their cost-effectiveness and efficiency over time. According to a report by the Global Valve Market Research, the adoption of screwed end ball valves can result in up to 25% reduction in operational costs, particularly in fluid control applications. This significant savings is primarily attributed to their durable construction and minimal maintenance requirements, offering manufacturers a long-term investment in reliability.

Moreover, a study conducted by the Industrial Valve Market Insights indicated that using screwed end ball valves can lead to a decrease in energy consumption by 15% compared to traditional valve types. This is critical in an age where energy efficiency is not only a priority for operational costs but also for environmental sustainability. As industries aim to minimize their carbon footprints, investing in efficient valve technologies like screwed end ball valves is proving to be a strategic move that aligns both economic and ecological goals.