-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

Ball valves are essential components in various industries. They offer reliable control over fluid flow. Understanding how these valves work is crucial for effective application.

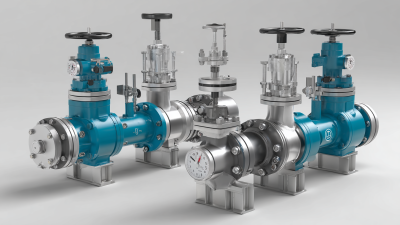

These valves feature a spherical disc that rotates within the body. When the ball is aligned with the flow, it allows fluid to pass through. When rotated, it blocks the flow entirely. This mechanism provides quick and efficient operation.

Ball valves are known for their durability and low maintenance. They are designed to handle high pressures and temperatures. However, incorrect installation can lead to leaks. Regular inspection is necessary to ensure they perform optimally. Overall, ball valves play a vital role in fluid management systems.

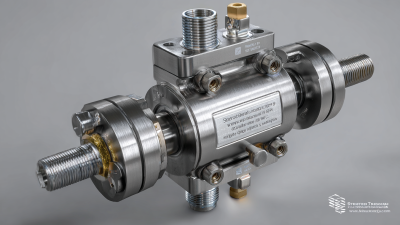

A ball valve is a type of valve that uses a spherical disc to control the flow of fluids. This spherical element, or ball, has a hole through its center that aligns with the pipe when open. When the ball is rotated, the hole blocks the flow, creating a tight seal. This simple yet effective design makes ball valves popular in various applications.

These valves are known for their durability and reliability. They can handle high-pressure and high-temperature environments. However, they are not always perfect. Over time, seals can wear out, leading to leaks. Regular maintenance is essential for optimal performance. Some users find it challenging to install, and improper installation can lead to functional issues.

Overall, ball valves offer a straightforward mechanism for fluid control. Their ease of use is a major advantage, but awareness of their limitations is crucial. Understanding these factors can help in selecting the right valve for specific needs. Proper evaluation and planning can lead to better outcomes in various industries.

A ball valve is a type of valve that controls flow using a spherical disc. This disc, or ball, has a hole through the center. When the ball is positioned so the hole is in line with the flow, the valve is open. When it’s turned perpendicular to the flow, the valve is closed.

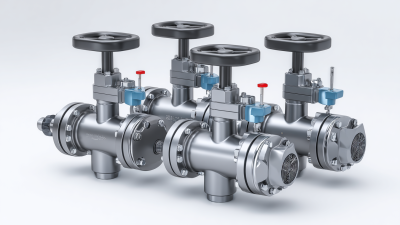

The main components of a ball valve include the body, the ball, and the stem. The body encases all parts, providing strength and support. The ball pivots to either allow or restrict flow. The stem connects the ball to the handle, allowing users to control the valve. Seals and seats are also crucial. They provide a tight fit, preventing leaks.

Tip: Regular maintenance is vital for optimal performance. Check seals for wear and tear periodically. Keep the valve clean to avoid blockages.

Remember, ball valves can fail if not maintained well. It's important to listen for unusual noises and watch for leaks. They are also typically not suitable for throttling applications unless designed specifically for that.

Tip: Always ensure the valve is installed in the correct orientation. Misplaced valves can lead to operational issues.

A ball valve is a straightforward yet effective device used to control the flow of fluids. Its operation relies on a ball with a hole through its center, which acts as the closing mechanism. When the handle is turned, the ball rotates to either allow or block flow. This simplicity makes it suitable for various applications in plumbing.

Mechanically, ball valves function with precision. They feature a seat where the ball rests. When the valve is closed, the ball presses against the seat, creating a tight seal. This ensures minimal leakage. However, the materials used in the valve can wear over time. Regular checks are crucial. Sometimes the valve may not fully close, allowing slight leaks.

It's vital to consider installation. A misaligned valve can lead to malfunction. Even experienced users can make mistakes. Proper torque settings must be followed. This ensures the ball moves freely without being stuck. Over time, accumulated debris can complicate the operation. It's important to maintain and inspect ball valves regularly.

Ball valves are popular in various industries, primarily due to their efficiency and versatility. One key advantage of using ball valves is their exceptional sealing capability. A ball valve's design features a spherical disc that rotates to either allow or block flow. When fully open, they create a straight path for fluids, minimizing pressure loss.

Data from the Flow Control Industry Report indicates that ball valves typically offer a leak rate of 0.1% of the full-flow capacity. This impressive performance enhances system reliability and safety, especially in critical applications like water treatment and oil refining. Additionally, ball valves have fewer moving parts compared to other valve types, contributing to their longevity and reduced maintenance costs.

Tips: Regular inspections can mitigate potential wear and tear. Watch for any leaks during high-pressure operations. Consider temperature limits; not all ball valves perform equally in extreme conditions. Always consult technical specifications before installation to ensure proper compatibility with your system.

| Feature | Description | Advantages |

|---|---|---|

| Operation | Uses a spherical disk to control flow | Quick and easy operation |

| Sealing | Provides a tight seal when closed | Minimizes leaks; reduces maintenance |

| Durability | Made from robust materials | Long lifespan in various applications |

| Flow Capacity | Full bore design allows for maximum flow | High efficiency in fluid transfer |

| Applications | Used in various industries like water, oil, and gas | Versatile and adaptable to different media |

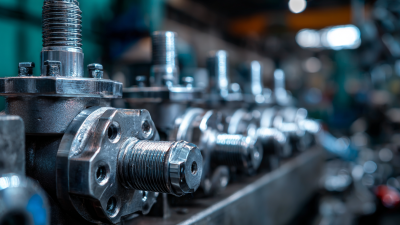

Ball valves are crucial in various industries due to their versatility and reliability. In the oil and gas sector, they control the flow of fluids under high pressure. A report from Research and Markets indicates that the global ball valve market is expected to reach USD 18.9 billion by 2026, highlighting their importance. In water and wastewater management, ball valves ensure efficient regulation of water flow, playing a vital role in treatment processes.

In the chemical industry, they provide safety in handling corrosive substances. Their tight sealing capabilities prevent leaks, which is critical for maintaining safety standards. The pharmaceutical sector also relies heavily on ball valves for sterile applications, where contamination must be avoided. Engineers often appreciate ball valves for their simple operation and minimal maintenance needs.

**Tip:** Regularly inspect ball valves for signs of wear or damage. Early detection can lead to cost savings.

Ball valves are not without challenges. They may not perform well in low flow conditions, causing turbulence. This can lead to flow noise and increased erosion inside the valve. Redundant systems may be needed to mitigate these issues in certain applications. Understanding the limitations of ball valves is key for optimal performance.

**Tip:** Consider the specific application demands when selecting valves to ensure compatibility.