-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

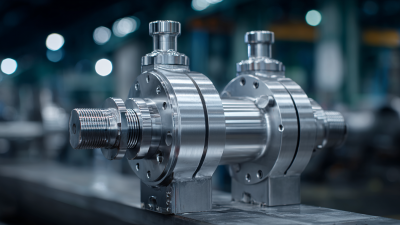

In the realm of industrial applications, the choice of valve type is crucial for ensuring optimal performance and efficiency. Among the various types of valves available, the Trunnion Mounted Valve stands out due to its unique design and functionality. This particular valve type is engineered to handle high-pressure and high-temperature conditions, making it an essential component in sectors such as oil and gas, chemical manufacturing, and water treatment. The robust construction of the Trunnion Mounted Valve, which features a trunnion support system for the ball, provides remarkable stability during operation.

The advantages of implementing Trunnion Mounted Valves in industrial settings are numerous and significant. Firstly, their ability to maintain tight sealing under extreme pressures leads to enhanced safety and reduced risk of leaks. Additionally, these valves offer excellent flow characteristics with minimized turbulence, which is critical in process-driven industries. Moreover, the longevity and reduced maintenance needs associated with Trunnion Mounted Valves translate into cost savings over time, solidifying their reputation as an innovative solution within the industrial sector. By exploring the top five benefits of these valves, this discussion will highlight why they are increasingly preferred for demanding applications.

Trunnion mounted valves offer significant advantages for enhanced flow control in industrial systems, making them a preferred choice for many applications. One of the primary benefits is their ability to handle high-pressure situations effectively. The trunnion design stabilizes the ball in the valve, reducing the risk of distortion under extreme conditions. This stability ensures a tighter seal, minimizing leaks and improving overall system integrity. As a result, industries that require reliable performance, such as oil and gas, benefit immensely from these valves.

Another advantage of trunnion mounted valves is their superior flow characteristics. They are designed to facilitate smooth flow, which helps to reduce turbulence and pressure drops within the system. This feature is particularly important in processes where precise control over flow rates is crucial. Additionally, the design allows for easier maintenance and longer service life, as the components can be replaced without needing to remove the entire valve from the pipeline. This not only saves time during maintenance but also reduces operational costs in the long run. Thus, the use of trunnion mounted valves significantly improves efficiency in industrial applications.

Trunnion mounted valves are increasingly favored in industrial applications due to their inherent design advantages, particularly in high-pressure environments. One of the most significant benefits is their improved stability. Unlike traditional floating valves, trunnion mounted designs feature a fixed axis, which helps in maintaining alignment, especially under high-pressure conditions. This stability significantly reduces the risk of valve seat wear and enhances the overall longevity of the valve. As a result, industries that deal with aggressive fluids or extreme pressures can rely on trunnion valves for consistent performance.

In addition to their stability, trunnion mounted valves require reduced torque requirements during operation. This is crucial in high-pressure applications where excessive force can lead to equipment failure or operational hazards. The design facilitates even distribution of pressure across the seat and stem, minimizing the effort needed to open and close the valve. Operators benefit from lower power consumption and less strain on actuators, leading to increased efficiency and extended service intervals. Consequently, the combination of stability and reduced torque requirements makes trunnion mounted valves an optimal choice for industrial settings requiring robust and reliable solutions.

This chart illustrates the top five advantages of using trunnion mounted valves in industrial applications. Each advantage is scored based on its performance and impact, demonstrating the strengths of this valve design in various high-pressure scenarios.

Trunnion mounted valves offer several advantages in industrial applications,

particularly when it comes to extending their service life by minimizing wear and tear.

By design, these valves stand out due to their unique support structure which distributes stress more evenly, thereby reducing the impact on critical components.

A recent report from the Valve Manufacturers Association highlights that trunnion mounted valves can reduce maintenance costs by up to

30% when compared to standard valve designs, a testament to their durability and efficiency.

Additionally, the construction of trunnion mounted valves allows for greater resistance to vibration and load forces, which are critical

in high-demand environments such as oil and gas or chemical processing. This stability is similar

to advancements seen in mountain bike shock technology, where improved designs are responding effectively to the forces exerted on them,

leading to reduced wear. Industry data indicates that with proper installation and maintenance, trunnion mounted valves can last significantly

longer than conventional models, with service intervals extended by as much as 50%.

This longevity not only translates to cost savings but also enhances operational reliability, making them an essential choice for industries

that prioritize efficiency and minimal downtime.

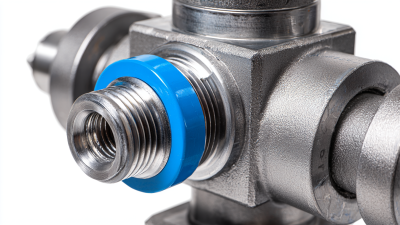

Trunnion mounted valves offer significant benefits in industrial applications, particularly when it comes to maintenance. One of the key advantages is the design that facilitates easier access to internal components. This allows maintenance personnel to perform inspections and repairs efficiently, reducing downtime and associated costs. Unlike traditional valve designs, trunnion mounted valves have a robust structure that minimizes wear and tear, which is crucial in high-pressure environments. This durability not only extends the life of the valve but also simplifies maintenance schedules, allowing for more predictable and manageable operations.

Moreover, the modular design of trunnion mounted valves enables straightforward component replacement. When parts wear out, they can often be replaced without needing to disturb the entire valve system. This feature significantly speeds up maintenance procedures and enhances operational efficiency. Additionally, the ability to isolate these valves during maintenance allows other parts of the system to remain operational, thereby increasing overall productivity. As a result, industries can achieve better performance and reliability while minimizing disruptions in their processes.

| Advantage | Description | Impact on Maintenance | Example Use Case |

|---|---|---|---|

| Reduced Wear | Trunnion mounted valves distribute load evenly, minimizing wear and extending lifespan. | Less frequent replacements lead to lower maintenance costs. | Oil & Gas piping systems. |

| Ease of Maintenance | Designed for easy access to internal components for maintenance. | Simplifies routine checks, reducing downtime. | Water treatment facilities. |

| Operational Safety | Fewer moving parts reduces the risk of failure during operation. | Enhances safety protocols, lowering risk of accidents. | Chemical processing plants. |

| Compact Design | Trunnion mounted valves require less space compared to traditional valves. | Allows for easier integration into existing systems. | Power generation facilities. |

| Versatile Application | Can be used in a variety of industries for different fluid types. | Reduces need for multiple valve types, simplifying inventory. | Manufacturing and processing industries. |

Trunnion mounted valves offer significant cost-effectiveness for long-term industrial projects due to their enhanced durability and reliability. Unlike conventional valves, trunnion mounted designs feature a supported stem that minimizes wear and tear, allowing them to maintain functionality even under high pressure and temperature variances. This durability translates to reduced maintenance costs and less frequent replacements, which can significantly lower the overall project expenses over time.

Furthermore, the operational efficiency of trunnion mounted valves contributes to their cost-effectiveness. With their ability to handle large flow volumes and provide precise control, these valves can enhance system performance, reducing energy consumption and operational downtime. For industries that rely heavily on continuous processes, the initial investment in trunnion mounted valves is outweighed by the savings accrued from lower maintenance needs and improved efficiency, making them a smart choice for any long-term industrial application.