-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

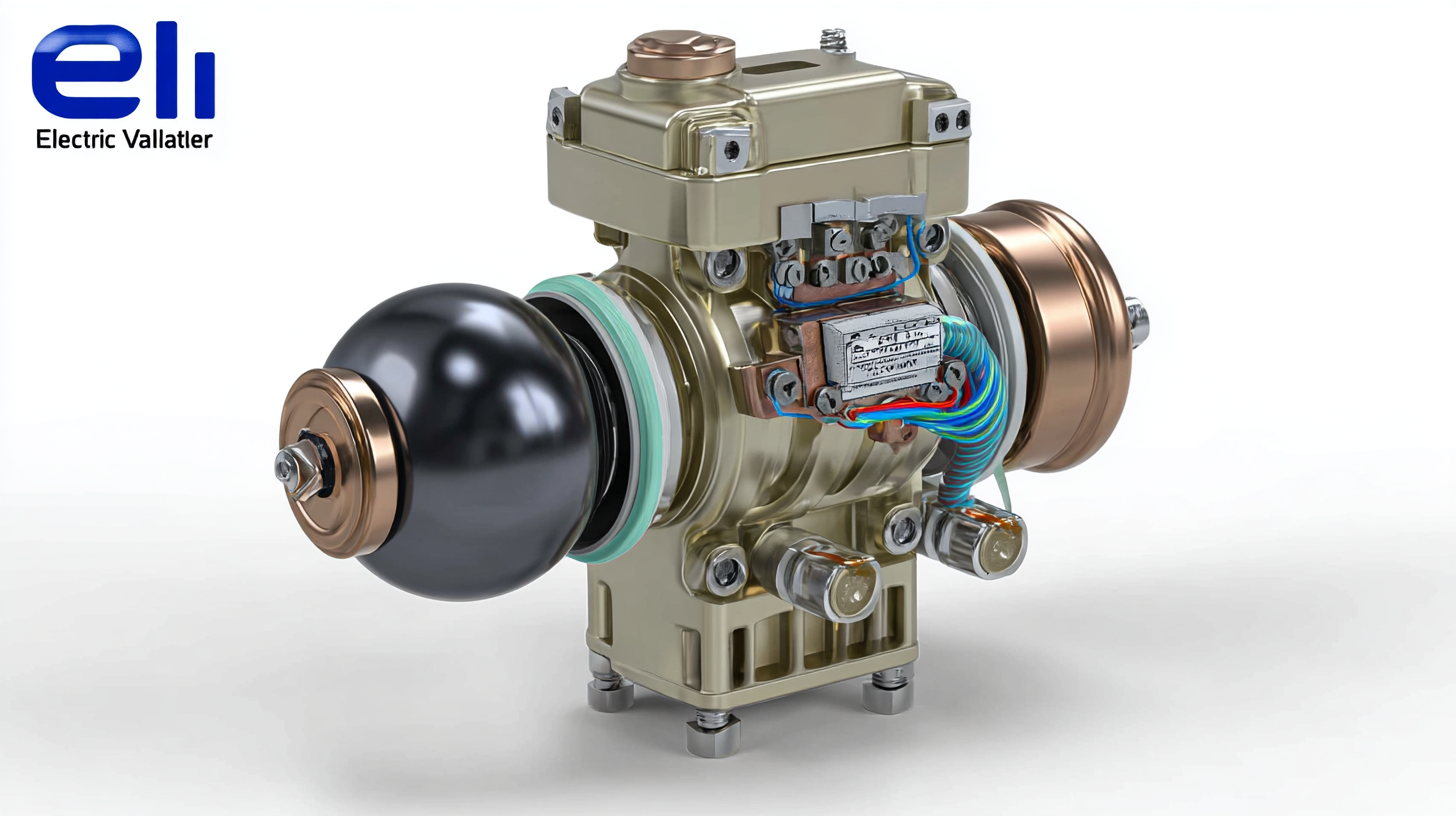

In today's fast-paced industrial landscape, the need for efficient and reliable control mechanisms has never been more crucial, making the Electric Ball Valve an essential component for various applications. The Electric Ball Valve stands out due to its impressive advantages, including precise flow control, quick responsiveness, and reduced manual effort. By integrating advanced technology into traditional ball valve design, manufacturers have developed solutions that not only enhance operational efficiency but also significantly lower maintenance costs over time.

In this blog, we will delve into the detailed technical specifications of the best Electric Ball Valves available, exploring their capabilities and functionalities. Additionally, we will guide you through how to select and implement these valves in your systems effectively, ensuring optimal performance and reliability for your specific needs. Join us as we uncover the transformative benefits of utilizing Electric Ball Valves in diverse applications, paving the way for smarter and more streamlined operations.

Electric ball valves have gained significant traction in modern industrial applications due to their enhanced efficiency and reliability. According to a report by Markets and Markets, the global electric valve market is projected to grow from $5.1 billion in 2023 to $7.0 billion by 2028, reflecting a compound annual growth rate (CAGR) of 6.7%. This growth is largely driven by the adoption of automation in various industries, where electric ball valves provide precise control of fluid flow, reducing the risk of leakage and ensuring smooth operations.

One of the key benefits of electric ball valves is their ability to minimize energy consumption. With advancements in smart technology, these valves can operate on demand, adjusting to the specific requirements of the system. A study by Grand View Research indicates that energy-efficient valves can reduce operational costs by up to 20%. Furthermore, the integration of electric ball valves with IoT (Internet of Things) solutions enables real-time monitoring and diagnostics, leading to proactive maintenance and less downtime. This is particularly valuable in sectors like oil and gas, where maintaining flow integrity is critical for safety and efficiency.

Chinese manufacturing has become synonymous with quality and innovation, particularly in the production of electric ball valves. By leveraging advanced technology and rigorous quality control processes, Chinese manufacturers have set a high standard in the industry. The precision engineering involved in creating these valves ensures durability, reliability, and optimal performance in various applications, ranging from industrial pipelines to residential water systems.

One of the standout features of the best electric ball valves produced in China is their adaptability. These valves can be equipped with various actuators and control systems to suit specific operational needs, facilitating seamless integration into existing systems. Moreover, Chinese companies often prioritize research and development, leading to the introduction of cutting-edge designs that improve energy efficiency and reduce maintenance costs. This focus on innovation not only enhances functionality but also positions these products as cost-effective solutions for businesses looking to optimize their operations while ensuring top-tier performance.

When considering the best electric ball valve for your applications, it’s essential to recognize the key features that make them an outstanding choice. One primary advantage is their precise control capabilities. Electric ball valves enable consistent and accurate flow management, allowing for smooth operation across various processes. This precision is especially crucial in industries that demand stringent control over fluid dynamics, where even minor fluctuations can lead to significant inefficiencies or safety hazards.

Additionally, electric ball valves are renowned for their durability and minimal maintenance requirements. Constructed from robust materials, they can withstand harsh conditions, making them suitable for sectors such as water treatment, chemical processing, and HVAC systems. Their design minimizes wear and tear, reducing the frequency of replacements and repairs, which translates into cost savings over time. Moreover, the ease of integration with automated systems and remote operation enhances their functionality, facilitating modern advancements in industrial automation and smart systems. These features collectively position electric ball valves as a reliable and efficient choice for a wide range of applications.

| Feature | Description | Advantage |

|---|---|---|

| Quick Operation | Fast opening and closing time for process control. | Increases efficiency in operations. |

| Precision Control | Allows precise flow regulation. | Enhances accuracy in flow management. |

| Energy Efficiency | Lower energy consumption compared to traditional valves. | Reduces operational costs. |

| Durability | Constructed from materials resistant to corrosion and wear. | Offers a longer lifespan and less maintenance. |

| Remote Operation | Can be operated from a distance using control systems. | Improves safety and convenience in hazardous environments. |

| Compact Design | Space-saving design suitable for various installations. | Easier integration into existing systems. |

Electric ball valves are becoming essential components in various industrial applications, thanks to their ability to provide precision control over fluid flow. The latest advancements in electric valve technology, such as innovative smart actuators, are enhancing reliability while reducing operational costs. These advancements enable businesses to optimize efficiency by ensuring accurate modulation of flow rates, which is vital in processes that require tight control to maintain performance and compliance with regulatory standards.

Maximizing efficiency with precision control in electric ball valves translates directly into improved performance across numerous sectors. For instance, modern pumping systems have been revolutionized to manage critical fluid systems more effectively, leading to significant gains in energy efficiency. The integration of double traveling valve technology in rod-pump systems exemplifies how traditional approaches are being refined to boost overall efficiency, making operations not only smoother but also more environmentally friendly by minimizing waste and maximizing resource utilization. In this context, the strategic use of electric ball valves is paramount for industries aiming to adhere to sustainability goals while enhancing their bottom line.

When it comes to industrial applications, choosing the right equipment can significantly impact your long-term operational costs. Electric ball valves have gained popularity for their efficiency and reliability, but one of the most compelling reasons to adopt them is their cost-effectiveness. Unlike traditional options, electric ball valves offer precise control and automation, which in turn reduces waste and energy consumption. This leads to substantial savings over time, making them an attractive investment for various industries.

Tip: When selecting an electric ball valve, consider opting for models with energy-efficient actuators. This choice not only enhances your savings but also minimizes your environmental footprint.

Moreover, the maintenance required for electric ball valves is generally lower than that of mechanical counterparts. With fewer moving parts and the elimination of manual operation, these valves are less prone to wear and tear. This reliability translates to reduced downtime and lower maintenance costs in the long run.

Moreover, the maintenance required for electric ball valves is generally lower than that of mechanical counterparts. With fewer moving parts and the elimination of manual operation, these valves are less prone to wear and tear. This reliability translates to reduced downtime and lower maintenance costs in the long run.

Tip: Implement a regular maintenance schedule for your electric ball valves. Keeping an eye on their performance can prevent minor issues from escalating into costly repairs.